Advances in thin-film coating technology during the past decades have focused on improving the quality of deposited layers through refinements in materials and deposition processes. Material improvements have included lowering impurity content, controlling chemical composition, and preparing physical forms that increase source utilization efficiency. Chemical processing has eliminated impurity-related detrimental contamination; reduction of the concentration of multiple oxidation states, that can introduce a variety of evaporation or sputtering efficiencies, has resulted in better repeatability of film composition and morphology.

Deposition processes have evolved in conjunction with greater demands on optical and mechanical film quality, durability requirements, and expanded applications. The introduction of new materials, especially relevant to mechanical properties, has also driven deposition process development. It has been known for some time that the energetics of the deposition process play the dominant role in not only film morphology and density, and therefore strength, but also composition as it influences transmission losses and high-energy laser damage thresholds.

The original Structure-Zone Model (SZM) proposed by Movchan and Demchishin related growth micro-structure to substrate temperature, T, which was the source of morphological energy [1]. The microstructure progresses from one that is characterized by low packing densities at low temperatures and large void volume, to one that is more densely packed in columnar structures at higher temperatures. Even at high temperatures, the packing densities deviated from bulk-like and exhibit stress. Later researchers included the influence of process pressure and ion energy in ion-assisted and sputter deposition.

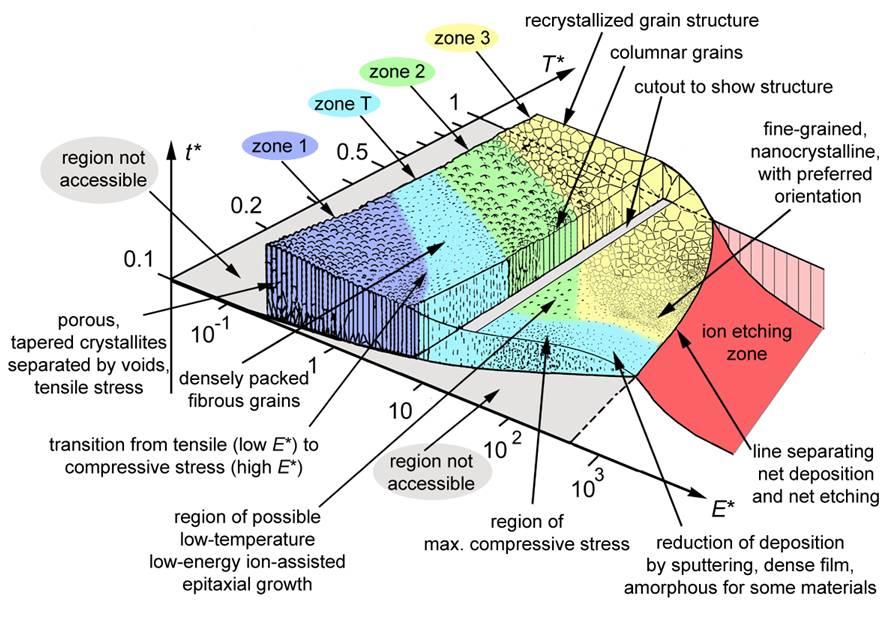

The SZM in Figure 1 summarizes the progression of deposition techniques from zones of low-energy thermal evaporation to zones of high-energy ion-beam and plasma-assisted processes.

Figure 1. The structure-zone model of thin-film morphology as determined by deposition process energy and extended by Anders to include sputtering energies. Citation: Andre Anders, Thin Solid Films, V58 Issue 15, 4087-4090 (2010) [2].

The revised SZM of Figure 1 relates morphology to the normalized deposition energy, E, and has been expanded to include high-power impulse magnetron sputtering and cathodic arc deposition. The latter two processes produce high densities of highly-energetic ions. The energy axis is proportional to ion kinetic energy expressed in eV. Typical energies for thermal evaporation are a few 10ths of an eV; for IAD, 50 – 70 eV; and for magnetron sputtering >10 eV.

Other parameters specific to the process play interdependent roles in determining film growth characteristics. From the diagram, we see that the microstructure progresses to compact smaller grain sizes as substrate temperature or energy is increased, even approaching amorphous. Higher kinetic energy promotes greater mobility on the substrate surface that in turn enables tighter nucleation and denser growth coverage of the surface. Ion kinetic energy substitutes for high substrate temperature in forming fine-grained compact layers, thus permitting deposition on temperature-sensitive substrates through high energy, low-temperature, processes. The excess energy also participates chemical reaction, for example in promoting oxidation and adherence to the substrate. Anders emphasizes that a multi-dimensional diagram is required to truly describe the complex growth dynamics and reactivity of thin layers [2]. For example, while compaction increases with energy, the sputtering effect dominates over growth at energies above certain values.