The wavelength of light imposes a limit on the smallest feature that can be resolved or imaged. This explains the motivation to extend optical systems to shorter wavelengths than visible light and into the short-wave ultra-violet (UV) region. Here we will introduce information about newly processed deep ultra violet (DUV) coating materials as discussed in earlier issues of Coating Materials News [See References 1, 2].

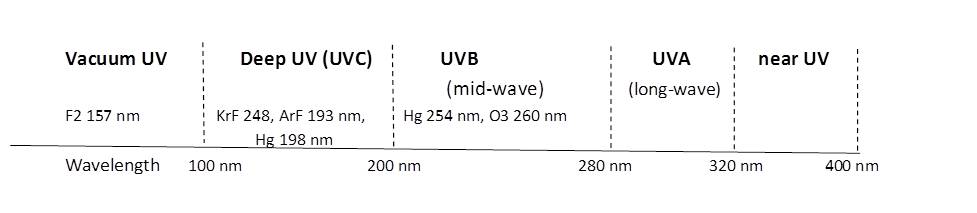

The UV spectrum is illustrated in Figure 1. The deep UV (DUV) region occupies wavelengths between 280 nm and ~200 nm, about half that of visible light. Typical light sources that are used in the regions of the UV spectrum are noted. Included is the single important wavelength of F2 at 157 nm used for high-density photo-lithography.

Figure 1: UV Spectrum

DUV optics is the backbone of many critical applications. Among these are nano-fab technologies that include: nano-meter scale photolithography for semiconductor patterning, high-density data storage, laser eye surgery (LASIK™), medical and dental surgery, high-energy laser applications, and sterilization and water purification. Another application is for UV LEDs that operate at 255 nm. These are compact, durable, lightweight devices that will be reliable replacements for mercury lamps and other bulky or inefficient elements.

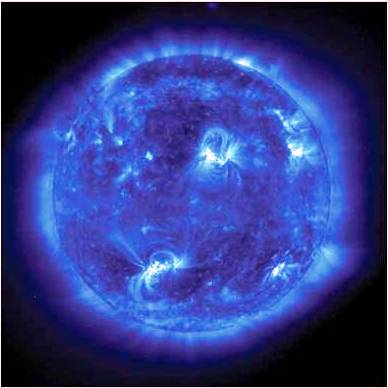

DUV optics and devices can also be employed to excite fluorescence and phosphorescence of specific mineral elements and novel compounds. That in turn has several uses, such as identifying mineral compositions on remote locations such as planet surfaces; or to produce high quality, intense light sources. A very specialized scientific application of UV light and devices is to monitor activity of the sun’s surface features, as illustrated in the following Image.

UV image of the sun showing flares and spicules on the surface. (NASA).

The candidate coating materials capable of transmitting or reflecting short DUV wavelengths are limited. Possibilities include metal oxide compounds ZrO2 and HfO2 which are usable to wavelengths ~250 nm, and SiO2 and Al2O3 which are transmissive to ~225 nm. At shorter wavelengths, absorption limits the transparency and laser damage-resistance of oxide coatings. Coatings intended for critical applications at shorter wavelengths than ~250 nm must therefore be composed of fluoride compounds. Optical coatings such as anti-reflecting (AR), high reflecting, polarizing, and beam-dividing components are deposited on lens or window substrates that have low absorption at DUV wavelengths.